.jpg)

How does a servo motor work? A servo motor is an electromechanical device that produces torque and velocity based on the supplied current and voltage. A servo motor works as part of a closed loop system providing torque and velocity as commanded from a servo controller utilizing a feedback device to close the loop. The feedback device supplies information such as current, velocity, or position to the servo controller, which adjusts the motor action depending on the commanded parameters.

Servo motors are available in an extensive variety of types, shapes and sizes. The term servo was first used in 1859 by Joseph Facort, who implemented a feedback mechanism to assist in steering a ship with steam to control the rudders. A servo motor is part of a servo mechanism consisting of three key elements – a motor, a feedback device, and control electronics. The motor can be AC or DC, brushed or brushless, rotary or linear, and of any size. The feedback device can be a potentiometer, Hall-effect device, tachometer, resolver, encoder, linear transducer, or any other sensor as appropriate. Completing the servo system is the control electronics that powers the motor and compares the feedback data and command reference to verify that the servo motor is operating as commanded. There are many types of servo motor applications, from simple DC motors used in hobby applications (such as model airplanes) to sophisticated brushless motors driven by complex motion controllers used for multi-axis machining centers. One example of a common servo mechanism is a vehicle cruise control that consists of an engine (the motor), a speed sensor (feedback), and electronics to compare the vehicle speed with the set speed. If the vehicle slows down, the sensor feeds this data to the electronics which, in turn, increases the gas to the engine to step up the speed to the desired set point – a simple closed loop system.

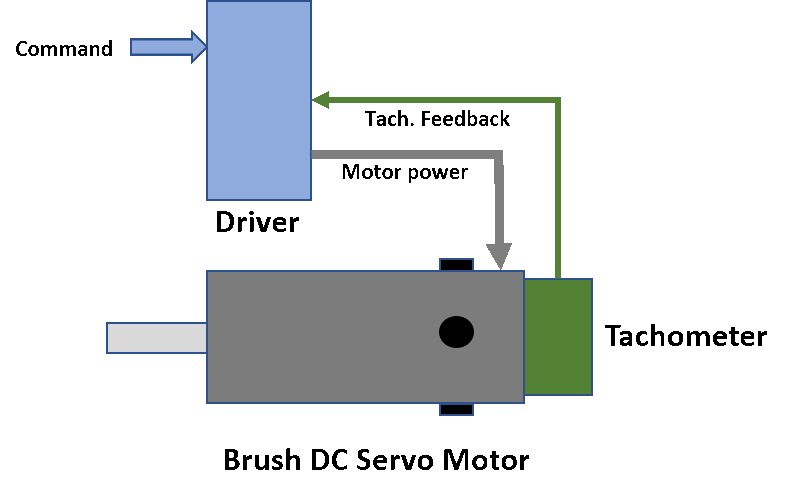

A simple industrial servo motor consists of a permanent magnet DC motor with an integral tachometer that provides an output voltage proportional to speed. The drive electronics delivers the necessary voltage and current to the motor based on the voltage fed back from the tachometer. In this example, a commanded speed (represented as a command reference voltage) is set in the driver, then the circuitry in the driver compares the tachometer feedback voltage and determines if the desired speed has been accomplished - known as a closed velocity loop. The velocity loop is monitoring the commanded velocity and tachometer feedback, while the driver adjusts the power to the motor to maintain the desired commanded velocity.

A simple industrial servo motor consists of a permanent magnet DC motor with an integral tachometer that provides an output voltage proportional to speed. The drive electronics delivers the necessary voltage and current to the motor based on the voltage fed back from the tachometer. In this example, a commanded speed (represented as a command reference voltage) is set in the driver, then the circuitry in the driver compares the tachometer feedback voltage and determines if the desired speed has been accomplished - known as a closed velocity loop. The velocity loop is monitoring the commanded velocity and tachometer feedback, while the driver adjusts the power to the motor to maintain the desired commanded velocity.

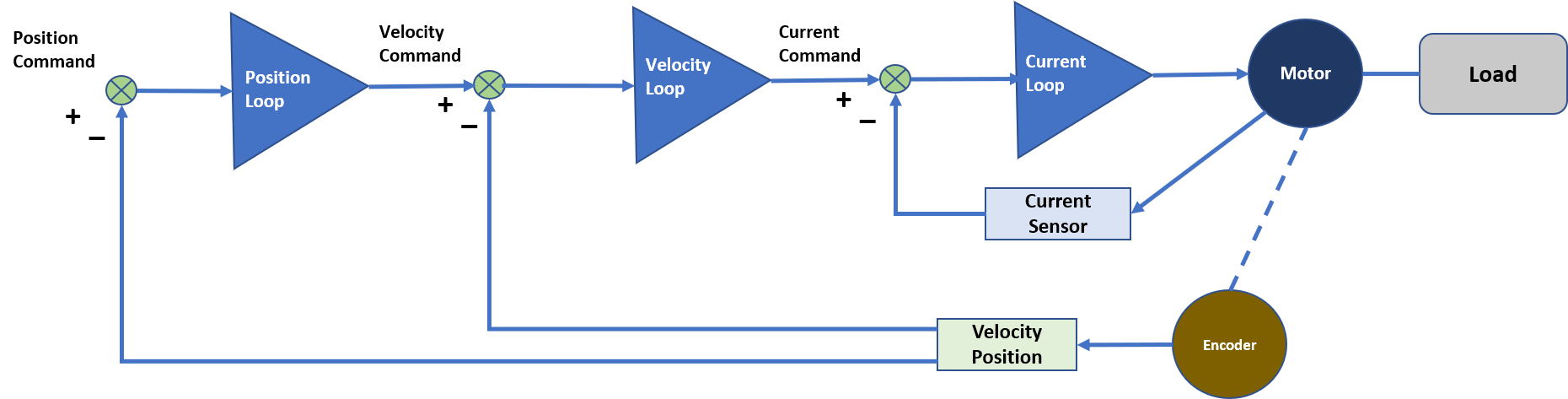

In a more sophisticated servo system, multiple embedded loops are tuned for optimal performance to provide precision motion control. The system consists of current, velocity, and position loops that utilize precision feedback elements. Each loop signals the subsequent loop and monitors the appropriate feedback elements to make real time corrections to match the commanded parameters.

The base loop is the current or torque loop. Current is proportional to torque in a rotary motor (or force in a linear motor), which provides acceleration or thrust. A current sensor is the device that provides feedback related to the current flowing through the motor. The sensor sends a signal back to the control electronics - typically an analog or digital signal proportional to the motor current. This signal is subtracted from the commanded signal. When the servo motor is at the commanded current, the loop will be satisfied until the current drops below the commanded current. The loop will then increase current until the commanded current is reached, with the cycle continuing at sub second update rates.

The velocity loop works in the same fashion with voltage proportional to velocity. The velocity loop sends the current loop a command to increase current (thus increasing voltage) when the velocity falls below the commanded velocity.

The position loop accepts a command for a PLC or motion controller, which in turn provides a velocity command that is fed to the velocity loop, which in turn commands the required current to accelerate, maintain, and decelerate the motor to move to the commanded position. All three loops work in optimized synchrony to provide smooth and precise control of the servo mechanism.