Metal forming machines rely on motors with optimum power and torque at high precision to make the perfect cuts, bends, perforations and stampings. This highly dynamic machine motion produces fast and repeatable processes while maintaining the strictest quality standards. By running at high speeds under full control, machines can realize increased throughput, and with dynamic motion, we can offer more innovative design capabilities. As part of a motion system, Kollmorgen’s motors create a smaller, lighter and more efficient metal forming machine that is easier to design, build, tune, commission and maintain.

We can help you achieve that goal for any metal forming machine. Engineer the exceptional with Kollmorgen.

Laser, Waterjet and Plasma Cutters >

Industrial cutting machines that use plasma, lasers and water to cut materials need high-torque and high-resolution feedback to minimize payload inertia and maximize control for faster, more precise cutting optimized for your application.

Bending Machines >

Bending machines use next-generation motors to produce complex bends in conduit, rebar, structural tubing and sheet metal. The motors maximize the speed, accuracy and repeatability to increase production quality and throughput.

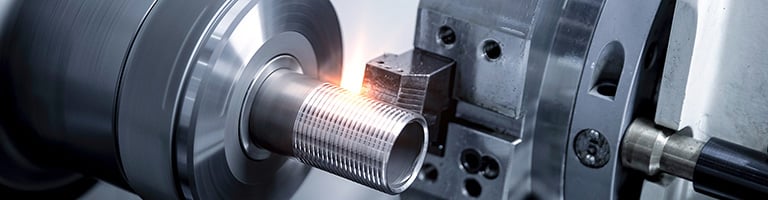

Machine Tools >

Machine tools, such as grinders and lathes, cut and shape metal, plastic and other materials with the greatest accuracy possible. Motion fine-tuned to the application eliminates backlash and compliance for better repeatability and precision.

Stamping and Press Brakes >

Multi-axis positioning systems with efficient torque and controlled power deliver high-quality part creation in a variety of precise, often-complex shapes without damaging the material.Engineer the Exceptional

Learn how to engineer exceptional machines, robots and vehicles with the highest-performing, most reliable motors, drives, automation solutions and more.