Keiding Reinvents Custom Packaging

Kollmorgen Delivers Power and Precision

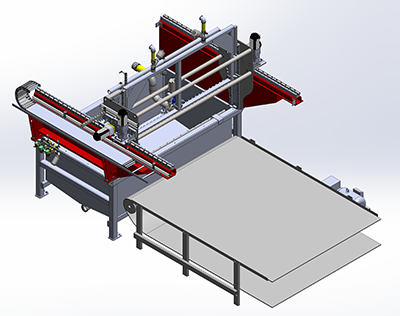

Keiding, Inc., leverages AKD® servo drives and AKM64L servo motors on a new molding machine to fuel state-of-the-art molded fiber packaging.

Fast Facts

Application:

Molded Fiber Packaging

Solutions Implemented:

AKD® drives with EtherNet/IP

AKM servo motors

Customer Since:

2017

Challenge and Results

Keiding pioneered the molded packaging industry in 1939, but in 2017 they were still operating machinery that had been built in the 1950s on a daily basis. As competitors entered the market using modern machinery, Mike Gehl, Keiding’s fourth-generation president, led the charge to build new machines by implementing industry expertise alongside new servo drive technologies. The result is a custom molding machine, which stands within the existing footprint of the original machinery, but also increases their customization capabilities.

Dean Kindrai of Neff Engineering and the liaison between Keiding and Kollmorgen described the conditions and requirements, “The loads are relatively high, some of the required moves are quick, and where the motors are located, there is a relatively high ambient temperature and high humidity.” With a firm grasp on the unique challenge in front of them, the team decided to replace old pneumatic systems with four Kollmorgen AKD drives with Ethernet IP interface and AKM64L servo motors with integral shaft seals.

Solutions

The partnership between Neff Engineering and Kollmorgen support engineers enabled the Keiding team to increase production efficiency, reduce maintenance and downtime, and attract new customers.

Advantages of Servo Motors over Pneumatic Systems

- Operators can adjust the speed of moves easily based on the specific product being run via the PLC

- Adjust the stroke lengths based on the product being run via the PLC

- Change from box motion to arching motion to improve cycle time

- Add a profile to the transfer that helps the product form better and dry faster

- Eliminate binding common in machines with multiple air cylinders

Gehl states, “With the new machine, we’re able to make parts we were never able to make before.” In the past, Keiding’s production facility ran four 24-hour days each week, but with production at full capacity they are making the move to run 24 hours per day, 7 days per week. Faster machines, driven by precision motor control coupled with 3D printing tooling expertise, have put Keiding on a growth track that will keep them ahead of the game. They are using Kollmorgen technology to break the mold in the mold making business.

ABOUT KOLLMORGEN

Since its founding in 1916, Kollmorgen’s innovative solutions have brought big ideas to life, kept the world safer, and improved peoples’ lives. Today, its world-class knowledge of motion systems and components, industry-leading quality, and deep expertise in linking and integrating standard and custom products continually delivers breakthrough solutions that are unmatched in performance, reliability, and ease-of-use. This gives machine builders around the world an irrefutable marketplace advantage and provides their customers with ultimate peace-of-mind. For further information please contact [email protected] or call us at 540-633-3545.

Molded Packaging Prototype

Combined teams from Keiding and Neff built the gantry used to form recycled paper into the desired shape.