When investing in a new or upgraded metal-cutting machine, industrial customers are looking for higher throughput, superior cut quality and greater ease of implementation and use. How can you establish your laser, waterjet or plasma cutting machine as the preferred choice for next-generation performance?

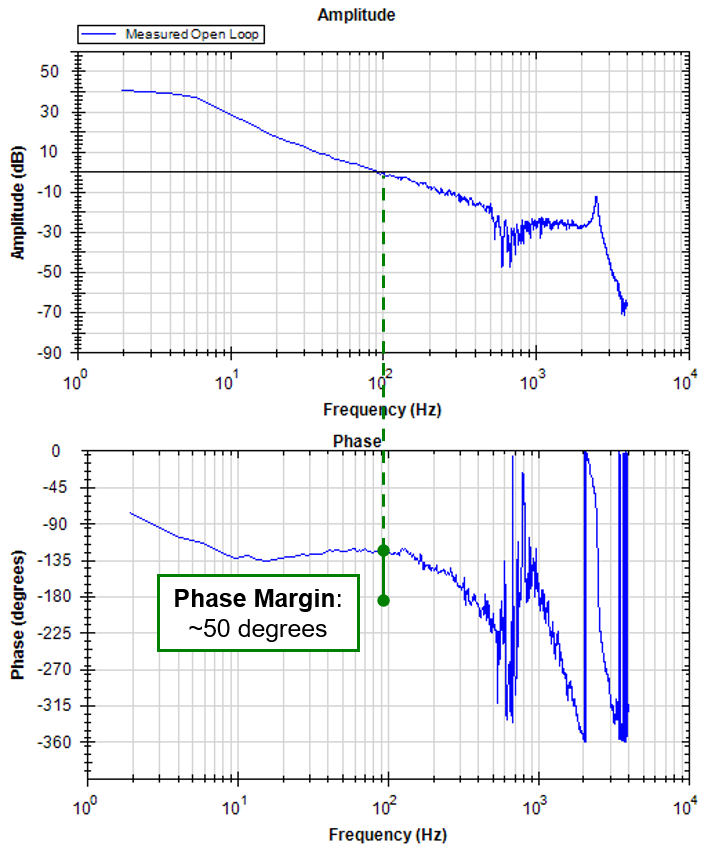

Motion makes the difference. Learn 5 key opportunities for optimizing your machine’s motion system — including how to choose the right fieldbus architecture, optimize control loop bandwidth, select and size servo motors for maximum performance, match feedback devices to your application requirements, and specify appropriate cables. Build a truly cutting-edge machine with the simple advice you’ll find in this white paper.