DECENTRALIZED SERVO TECHNOLOGY FOR TEST SYSTEMS

Providing orientation for materials

Swiss company MEquadrat AG builds test systems with decentralized servo technology from KOLLMORGEN

Materials with optoelectronic functions are an indispensable part of electrical components today. Users need to know the material’s precise internal molecular structure before the components are installed so that these then work reliably in the application. MEquadrat (ME2) builds test systems for this purpose that are designed as a rotary indexing table. Decentralized servo drives from KOLLMORGEN are placed on the rotary units for positioning the test specimens.

Slim, round like a pill, and with clearly defined edges, optoelectronic glass components generally look rather inconspicuous with their milky-white coloration. The minimalist appearance is the result of the manufacturing process in which the eventual components are cut from blocks in large quantities. Processes are required which reveal how the molecular structure has grown in the interior in order to ensure that the bulk material is suitable for installation in the device.

Providing orientation for disorder

Inspection systems from ME2 are used for determining the atomic structure of the glass-like materials clearly. The company from the district of Root in Switzerland specializes in test equipment technology. We build machines that have never been built before,” says Managing Director Stefan Nyffenegger with a smile, before noting that this is why ME2 is always more than happy to start introducing new technologies into machinery construction at a very early stage. This philosophy is reflected currently in a test system driven by decentralized servo drives from KOLLMORGEN’s AKD-N series. “This way we can determine the ideal installation location for the test specimens,” explains the mechatronics engineer. “We know their alignment and behavior precisely once they leave our system,” he adds.

Inspection systems from ME2 are used for determining the atomic structure of the glass-like materials clearly. The company from the district of Root in Switzerland specializes in test equipment technology. We build machines that have never been built before,” says Managing Director Stefan Nyffenegger with a smile, before noting that this is why ME2 is always more than happy to start introducing new technologies into machinery construction at a very early stage. This philosophy is reflected currently in a test system driven by decentralized servo drives from KOLLMORGEN’s AKD-N series. “This way we can determine the ideal installation location for the test specimens,” explains the mechatronics engineer. “We know their alignment and behavior precisely once they leave our system,” he adds.

The materials go through six test stations via a rotary table for the different measurement procedures. ME2 has placed six servo axes on the rotary table which raise the test specimens after each test step and move them to the next station working together with the rotary motion of the rotary indexing table. “The measurement stations are stationary in the machine, and we have to position the test specimens precisely to two-hundredths of a millimeter with the AKM servo motors,” says Felix Aeschimann, a software architect at ME2. The AKD-N decentralized servo drives drive compact AKM servo motors for this, which are connected in turn as handling axes with ball screws as a linear unit.

Everything on one continuous cable

“The great thing about the AKD-N is that we are able to connect it via a loop wiring system. We use just one cable for everything: power, communication and safety engineering,” says Stefan Nyffenegger. Another special feature of the structure for the decentralized servo drive technology is that there is also a slip ring placed between the AKD-C switch cabinet module and the six AKD-N servo drives also rotating on the rotary indexing table, in order to ensure that the test unit does not have to reverse and can instead continue traveling endlessly in a circle. The slip ring interrupts the cable connection between the power supply and the servo drives, which provided a new challenge in terms of the safety engineering. Although the combination of AKD-C and AKD-N features the TÜV-certified “Safe Torque Off” (STO) safety function, there is no longer any abatement provided when combined with the interconnected slip ring.

“The great thing about the AKD-N is that we are able to connect it via a loop wiring system. We use just one cable for everything: power, communication and safety engineering,” says Stefan Nyffenegger. Another special feature of the structure for the decentralized servo drive technology is that there is also a slip ring placed between the AKD-C switch cabinet module and the six AKD-N servo drives also rotating on the rotary indexing table, in order to ensure that the test unit does not have to reverse and can instead continue traveling endlessly in a circle. The slip ring interrupts the cable connection between the power supply and the servo drives, which provided a new challenge in terms of the safety engineering. Although the combination of AKD-C and AKD-N features the TÜV-certified “Safe Torque Off” (STO) safety function, there is no longer any abatement provided when combined with the interconnected slip ring.

Slip ring solution with Safety

Slip ring solution with SafetySafety torque off is a crucial function given the daily practice of production employees continuously accessing the machine. This is why KOLLMORGEN developed a TÜV-certified solution working together with slip ring manufacturer Stemmann from the district of Schüttdorf, and was then able to provide these to ME2 as a ready-to-install drive solution. The slip ring is installed in the central axis of the rotary table and combined with the single-cable connection technology, forms a very slim installation that continues to operate, since the power, communication and safety engineering are looped through to the next device by an AKD-N servo inverter like a string of pearls. The benefit provided by this structure can be seen from the switch cabinet as well as the connection from there to the machine. The ultra-slim circuit groups can barely be seen, which also means there are no problems with cumbersome cable trays or with time-consuming installation processes.

Slip ring solution with SafetySafety torque off is a crucial function given the daily practice of production employees continuously accessing the machine. This is why KOLLMORGEN developed a TÜV-certified solution working together with slip ring manufacturer Stemmann from the district of Schüttdorf, and was then able to provide these to ME2 as a ready-to-install drive solution. The slip ring is installed in the central axis of the rotary table and combined with the single-cable connection technology, forms a very slim installation that continues to operate, since the power, communication and safety engineering are looped through to the next device by an AKD-N servo inverter like a string of pearls. The benefit provided by this structure can be seen from the switch cabinet as well as the connection from there to the machine. The ultra-slim circuit groups can barely be seen, which also means there are no problems with cumbersome cable trays or with time-consuming installation processes.

ME2’s solution for implementing the machine control unit to the motion control is just as smart. A CompactRIO from National Instruments (NI) with LabVIEW environment is used as the computer center. ME2 uses this system for the actual laboratory processes for precise analysis of the components. “We are the only company in Switzerland that has been able to combine the CompactRIO and LabVIEW with so much motion control,” notes Felix Aeschimann. The NI Alliance Partner links the workflow commands for the motion control via Modbus with the new KOLLMORGEN Motion Controller PCMM.

The LabVIEW connection for the drives via the PCMM is one of the highlights of the engineering partnership between ME2 and KOLLMORGEN. “Manufacturer support is one of the most important factors when we are looking for a supplier that’s right for us,” says Nyffenegger. “We build special solutions, and this always involves challenges that need to be resolved quickly.” The aim is to get systems up and running as quickly as possible, as customers often specify short time frames from development to commissioning.

Faster installations mean more time for development

The Swiss company also believes that building the system at the latest possible stage is important following the development and design stages. “We are a small company and so are interested in short pre-financing times. This is why we purchase technology that is as far as possible modular and pre-assembled.” The sales director firmly believes that the cost part for installation and assembly needs to be as low as possible in terms of overall machine costs. “The less we wire up the better. We’re engineers and not electricians. ME2 earns its money from engineering services. That’s why complete systems from one source such as those from KOLLMORGEN are such a benefit to us.”

Author: Dipl.-Ing. Martin Zimmermann,

Author: Dipl.-Ing. Martin Zimmermann,

KAM Switzerland, KOLLMORGEN Switzerland

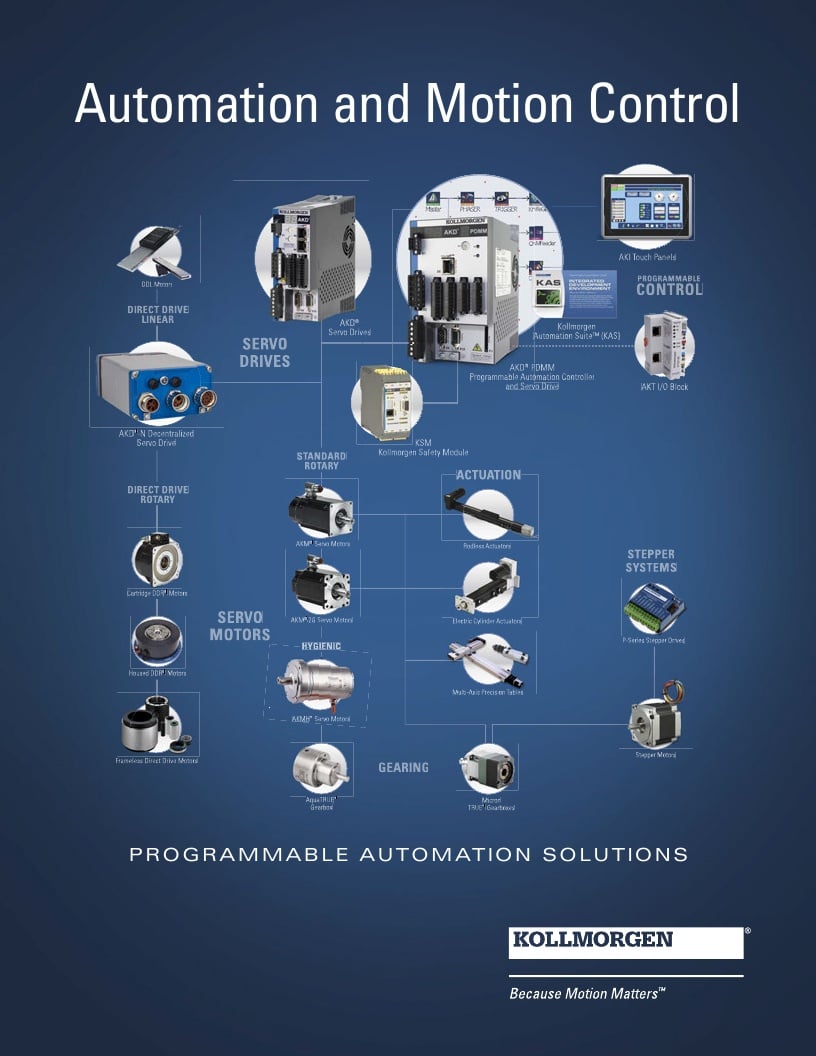

ABOUT KOLLMORGEN

Since its founding in 1916, Kollmorgen’s innovative solutions have brought big ideas to life, kept the world safer, and improved peoples’ lives. Today, its world-class knowledge of motion systems and components, industry-leading quality, and deep expertise in linking and integrating standard and custom products continually delivers breakthrough solutions that are unmatched in performance, reliability, and ease-of-use. This gives machine builders around the world an irrefutable marketplace advantage and provides their customers with ultimate peace-of-mind. For further information please contact [email protected] or visit our website www.kollmorgen.com/uk