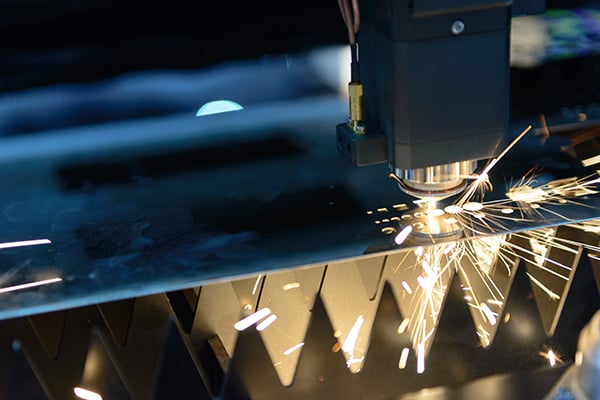

Discover the motion technologies that enable next-generation laser-cutting system performance. Read the details in our case study, “Enhancing Precision While Reducing Size, Weight and Cost,” then envision the possibilities for your own metal-cutting…

Learn how a major supplier of automated tube-cutting machines used direct-drive technology to transform metal-forming performance, precision and versatility. Get the details, and envision the possibilities for your own metal-cutting machine.

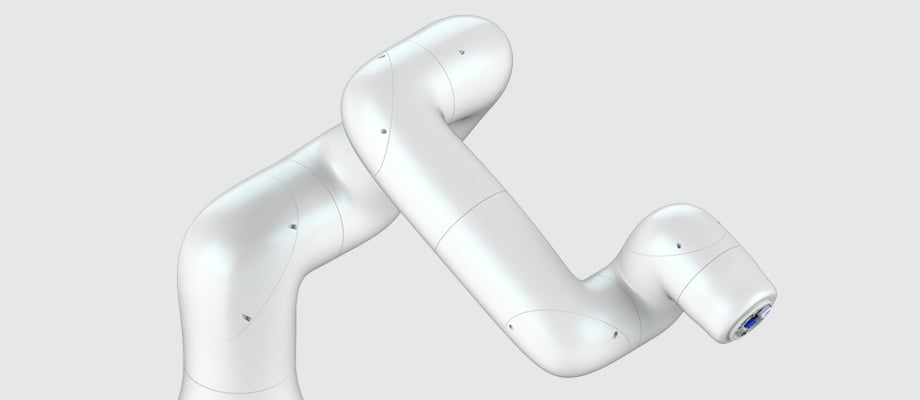

Learn how Kollmorgen servo technology is helping OEMs accelerate the design of next-generation prostheses and exoskeletons.

Innovation, competency, service. Through 60 years in business, these

three commitments have helped the Salvagnini Group achieve global

leadership in the field of sheet-metal processing equipment. As the

#1 worldwide supplier of panel benders, and one…

Kollmorgen has helped many companies in a variety of industries increase performance, quality, throughput, and reduce costs. Read about our partners' successes here.

Kollmorgen’s advanced motion products and expertise are helping save and improve lives. Learn how the new Genesis surgical robot incorporates torque-dense AKM servo motors with specialized, integrated encoders to revolutionize cardiac ablation…

The demand for battery-electric and plug-in hybrid electric vehicles is

rapidly growing, thanks to increasing manufacturing capacity, large-scale promotion, and widespread recognition of the urgent need to

reduce greenhouse gas emissions. Blade…

A new collaborative surgical robot helps surgeons do their best work, in more types of surgery, delivering better outcomes. TBM2G servo motors make it possible.

The development of photovoltaic and thermal solar energy—along with China’s rapidly growing capacity to manufacture them—has opened many new opportunities for sustainable energy production in international markets. At the same time, the demand for…

A company that specializes in creating cutting, placing and packaging machines looked to Kollmorgen for an innovative motor design. See how the AKMH motor met the strictest hygienic requirements and integrated with a third-party drive.

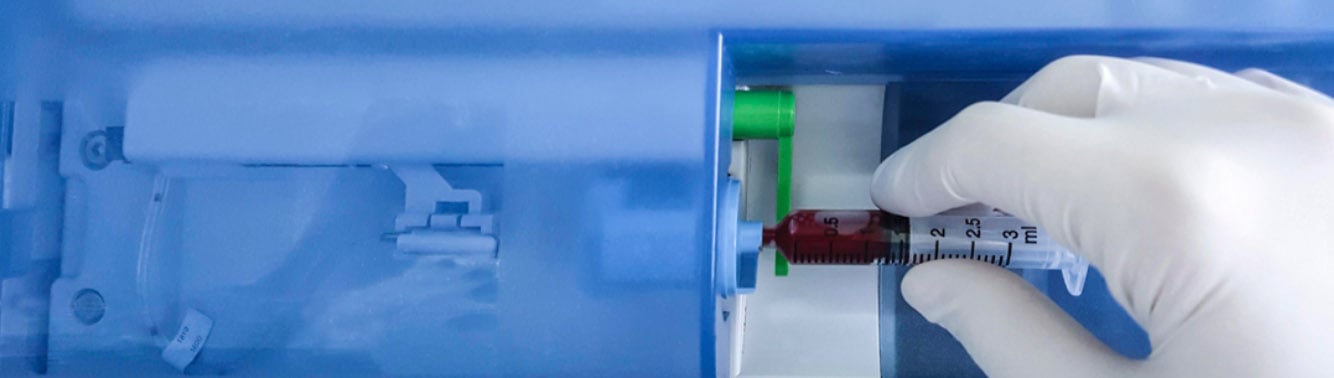

When the world became aware of the COVID-19 outbreak first identified in Wuhan, China, it quickly became clear that greatly increased diagnostic capacity would be needed. Early in the outbreak, one of the world’s largest producers of diagnostic…

The COVID-19 pandemic has created a massive spike in the demand for medical equipment in every region of the world, including personal protective equipment, laboratory test systems, ventilators and more. A major global supplier of blood gas analyzers…