30 % INCREASED PERFORMANCE : DOUBLE INNOVATION IN PAPER BAG MACHINE

Double Innovation In Paper Bag Machine

Automatic System offers 30% Increased Performance in Production and Mold-Switching Process

There is a slight difference in the operational flexibility of the paper bag machines produced in Turkey, from those produced in Europe. While the same product in Europe is manufactured as 500 kilograms, this number drops to 200 kilograms in Turkey.

Known for manufacturing paper bags, laminating and flexo-printing machines, Nort Makina has designed and developed a new paper bag-manufacturing machine that has increased production speed by 30 percent, automating the mold-switching process. Developed using standard technology, as well as specialised technology, the machine has a minimum of 8 rotational axes, and is capable of engaging as many as 30 rotational axes, depending on client specifications. All the electronic systems and software built into this machine, which produces far more products than counterparts on the market, were developed by Kollmorgen Elsim.

Consumption of plastic bags is continuing to decline, and they are being replaced by paper bags. Paper bag machines have a rather complicated structure, and under the present conditions, it takes a fair amount of time to switch molds when changing production. To solve such problems, Nort Makina has developed a new paper bag manufacturing machine in collaboration with Kollmorgen Elsim, trusted for their engineering and know-how. This newly developed machine is able to deliver in various dimensions and characteristics, and thus switch between different product processes several times a day. It takes a fair amount of time to switch molds in the production of different products in the machines that are currently in use, and company engineers are looking for new ways to tackle this issue. With this in mind, they conducted an intense R&D study to see how they could reduce delays between the manufacturing of different products.

Another important innovation is the approximately 30% increase in the production speed of the machine. While similar machines on the market generate 600-700 paper bags per minute in a manner that varies depending on the product dimensions, the new machine increased this number to the range of 900-1000. During the development of this technology, standard tests, as well as specialised tests, were conducted. Nort Makina Production Manager, Zekeriya Gungor, said, “There is a saying in manufacturing industry jargon that ‘the machine chooses the products’. A test you conduct with one product may not correspond to a similar product. This actually shows the quality of the machine”. He then went on to point out that they have received positive results in all of their testings. While the same product in Europe is manufactured as 500 kilograms, this number drops to 200 kilograms in Turkey, because that is the trend in demand, with which the manufacturer has to comply. If we take the daily production capacity of a machine as 1 tonne, and assume that 4 different products are manufactured within a day, an average of 4 product-switches would be necessary. When the switching time of each product is around 30 minutes, this implies that every day nearly 2 hours are spent on changing the machine-settings. This is a serious amount of time.

An Outstanding Machine Automation Solution

The Kollmorgen Automation Suite™, an outstanding machine automation solution, brings together a high level integrated and heuristic software programming environment with top of the range motion constituents and extraordinary joint engineering services in order to help construct a highly differentiated machine and a more profitable business. Providing intermediate-level computer performance, the Advanced Performance Programmable Automation Controller (AKD PDMM) provides the highest processor performance with Intel Celeron processor technology. The High Performance AKD PDMM product, which includes the 10” or 15” integrated screen options, offers superior computer performance employing processor technology integrating the Intel Core 2 Duo family of microchips

AKD® Advanced Kollmorgen Drives and Cartridge DDR Direct Drives

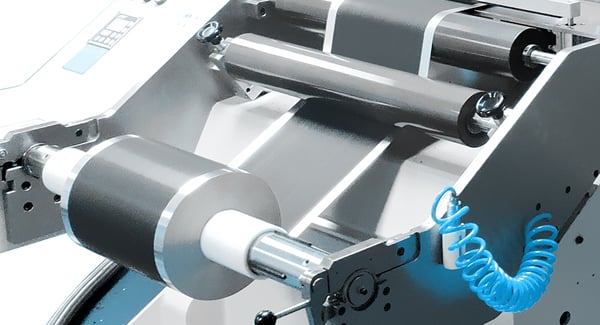

Comprising a complete range of ethernet-based servo drives that can easily be integrated into all types of applications, the Kollmorgen AKD® Series offers a plug-and-play startup system for instant and uninterrupted access to everything in the machine. Along with the top-of-the-range servo-components, the AKD drives offer industry-leading performance, communication options and power levels, all of which are produced in environmentally-friendly ways.

Combining seamless performance advantages with ease of full compound motor installation in machines, the Exclusive Cartridge DDR® motor has a unique bearing-free design feature that is directly attached to the load using an integrated factory-aligned high resolution feedback device, as well as machine bearings to support the rotor. Most models can be assembled in less than five minutes.

In order to shorten mold-switching times, Nort engineers conducted an automation-assisted study with Kollmorgen. As a result of these studies, with the innovations in the production line and adjustments in the software department, they managed to adapt the machine to use automatic measurement and thus switching. Evaluating Nort Makina’s collaboration with Kollmorgen Elsim, the Key Account Manager Gamze Yildiz states that Nort Makina had decided to conduct this application with Kollmorgen because they trusted their engineering and know-how.

All Kollmorgen Products in the Right Place

Success in machine manufacturing can be secured by using the right product in the right place. Prominent amongst products and systems in terms of the right place are the ‘servo systems’. At this point Kollmorgen technology comes into play. All the electronic systems and software within the advanced machine are developed by Kollmorgen, and the following Kollmorgen products are used in the project:

- AKD PDMM Motion Control (Superior speed industrial PC)

- AKD Servo Drive

- CDDR Direct Drive (The direct drive servo-motor provides outstanding sensitivity)

- AKM Servo Motor (Extra durable servo-motor with high torque within a small container)

Extra Durable Servo Motor with High Torque. Kollmorgen AKM™ synchronous servo motors are offering their users unprecedented choice and flexibility, with limitless joint design modification in over 500,000 standard products and practice. Thanks to this product, choosing the right motor optimised for special application needs has never been easier

Conclusion: Drawing Intense Pre-Launch Interest

This new machine developed by Nort is already attracting intense attention from the company’s current clients even though it has yet to be launched on the market. Nort Production Manager Zekeriya Gungor says, “Even though we haven’t yet launched the machine, we are already receiveing significant attention, especially from our current clients who follow us”. He adds: “We manufacture paper bags, laminating and flexo-printing machines. As a company, we produce bespoke projects in addition to our main product groups, conduct case studies and provide consulting services. We are capable of addressing all kinds of requirements in the best way. Kollmorgen has been an important, supportive partner to us throughout our entire and complex manufacturing and design process. We chose Kollmorgen for its positive contributions during our R&D and design processes, and for their product quality. A good technical service is just as important as good products”.

Author: Gamze Yildiz

Key Account Manager Kollmorgen Elsim

About Kollmorgen

Kollmorgen is a leading supplier of integrated automation and driver systems, as well as related components, aimed at machine manufacturers all over the world. With over 70 years of experience in Motion Control Design and application, as well as its extensive knowledge in the areas of production standards and bespoke solutions, Kollmorgen provides prominent solutions in terms of performance, quality, reliability and ease of use. As a result, our clients gain indisputable leverage in the market. www.kollmorgen.com/uk