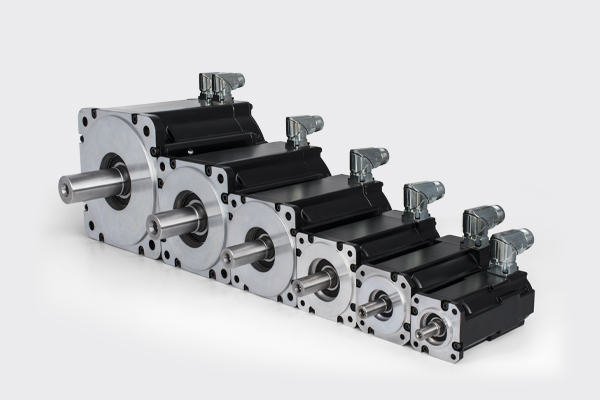

Most mining and construction applications require the application of substantial torque, for example to move earth or to carry and position heavy materials. Yet these applications are often space-constrained, requiring robots to be as compactly designed as possible. With industry-leading torque density, Kollmorgen’s AKM2G servo motors deliver all the torque you need in a 20% smaller package compared to other motors in their class.

All the Torque You Need in a Compact Footprint

Ready for Electrification?

Through improvements in permanent magnet materials, more efficient electromechanical designs and other technical innovations, advanced electric motors can now rival the power density of hydraulic motors. And electric motors deliver many benefits that are beyond the reach of hydraulics, including greater reliability, little or no maintenance, and no risk of environmentally damaging leaks. Learn more in our article,

Collaborative Engineering for Shorter Design Cycles

At Kollmorgen, progress in motion is a collaborative process governed by the specific needs of each industry and each customer we serve. Let’s work together, engineer-to-engineer, to address your unique challenges, shorten your design cycles and bring better underwater machines and submersible vehicles to market faster.