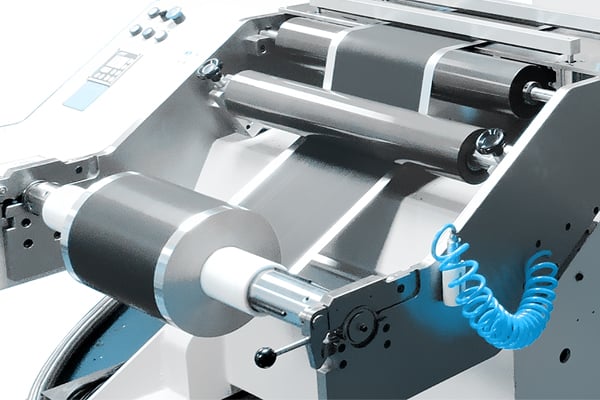

In lithium-ion battery production, the coating of metal foils to create pole pieces is a crucial step. The process must be carried out with utmost precision, with the results strictly monitored, in order to ensure the functionality and long-term reliability of each battery cell.

Using Kollmorgen direct drive technology, manufacturers are achieving coating accuracy of less than ±2 g/m2 and layer thickness accuracy of less than ±1 μm — while also increasing coating width from 1.5 m to 2 m and production speed from 60 m/min to over 100 m/min.