Kollmorgen Motors for Defense: Proven Processes, Reliable Delivery

Few business challenges are as formidable and complex as winning a defense contract. Program specifications, contractual obligations and provisioning requirements are all far more demanding than practically anything encountered in the civilian manufacturing world.

Risk mitigation is crucial at every stage to hit deadlines, transition successfully from prototype to full-rate production, and keep defense customers supplied throughout the program lifecycle.

Why Partner With Kollmorgen?

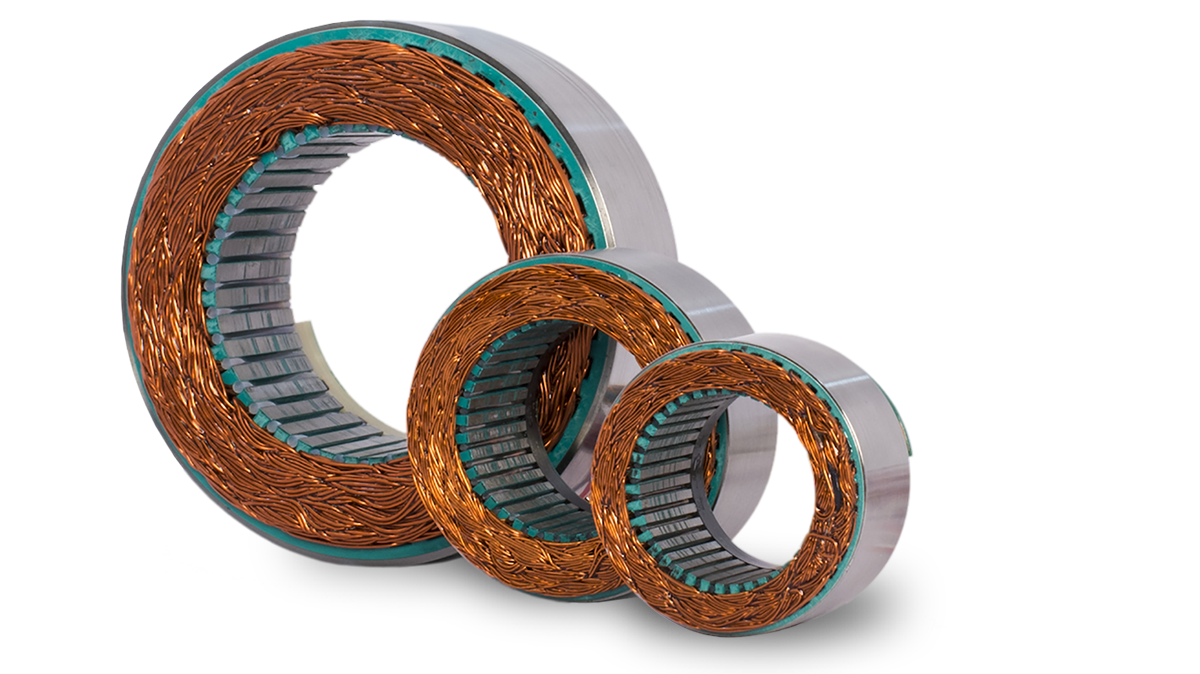

To win, you need a reliable partner. With more than 100 years of motion leadership, including over 70 years designing, manufacturing and supplying motion products for aerospace and defense applications, Kollmorgen delivers motors with proven reliability, from initial design through trusted service, in theaters of operation around the world.

Our deep knowledge of defense applications, collaborative engineering culture, custom capabilities and sustainable manufacturing processes provide the greatest assurance of program success. We deliver the knowledge, speed, adaptability, diligence, experience and resources to help you design the most effective motion systems for your defense programs and ensure their long-term motion success.

![]() Key Joint Milestones:

Key Joint Milestones:

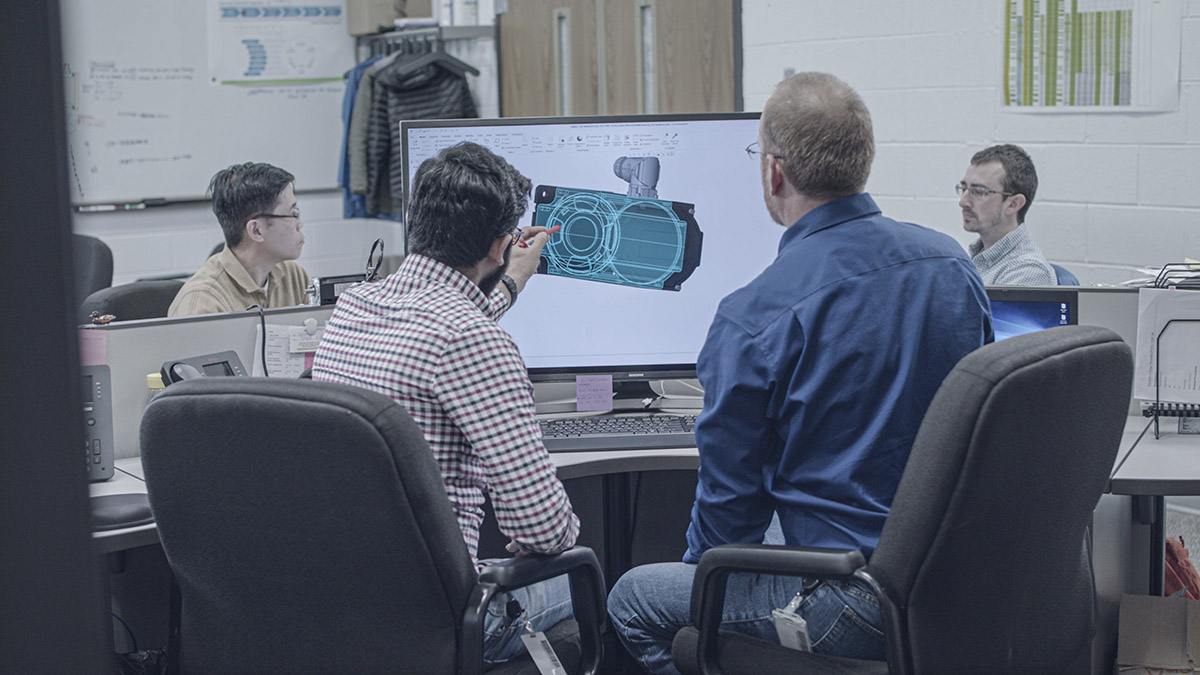

Knowledge: Initial Design

Kollmorgen is not a build-to-print shop. We know how to meet your performance and quality specifications with the most efficient and effective motor design, with assured manufacturability on your required scale and timeframe. We’re your collaborative partner, working with your engineering team to arrive at the optimum motor for performance, reliability and cost.

![]() Key Milestone: Joint specifications review

Key Milestone: Joint specifications review

Speed: Prototyping

Our prototyping teams have decades of experience, ensuring that the motors you specify work exactly as expected, right out of the box. We can provide fast-turn prototyping for the most challenging motor requirements—typically delivering what you need within just a few weeks. And because we maintain a broad and sophisticated portfolio of commercial off-the-shelf products—plus literally thousands of proven standard modifications—what would normally be considered a custom prototype is often a standard offering for Kollmorgen.

![]() Key Milestone: Preliminary design review

Key Milestone: Preliminary design review

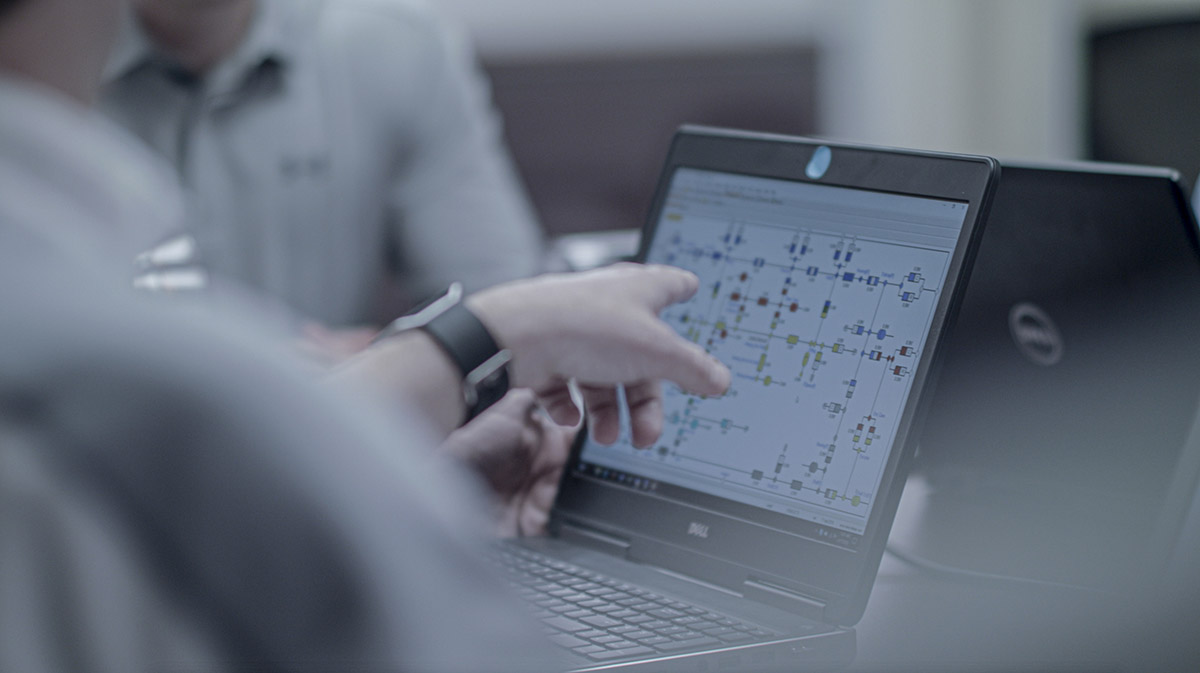

Adaptability: Iterative Design

Everything can look perfect in CAD, but upon physically constructing your prototype you will probably discover things you’d like to change or refine. We understand that, and are prepared to iterate motor designs rapidly for a perfect fit in your revised design. Adaptability is core to Kollmorgen’s identity, built into all of our design and manufacturing processes.

![]() Key Milestone: Intermediate design reviews

Key Milestone: Intermediate design reviews

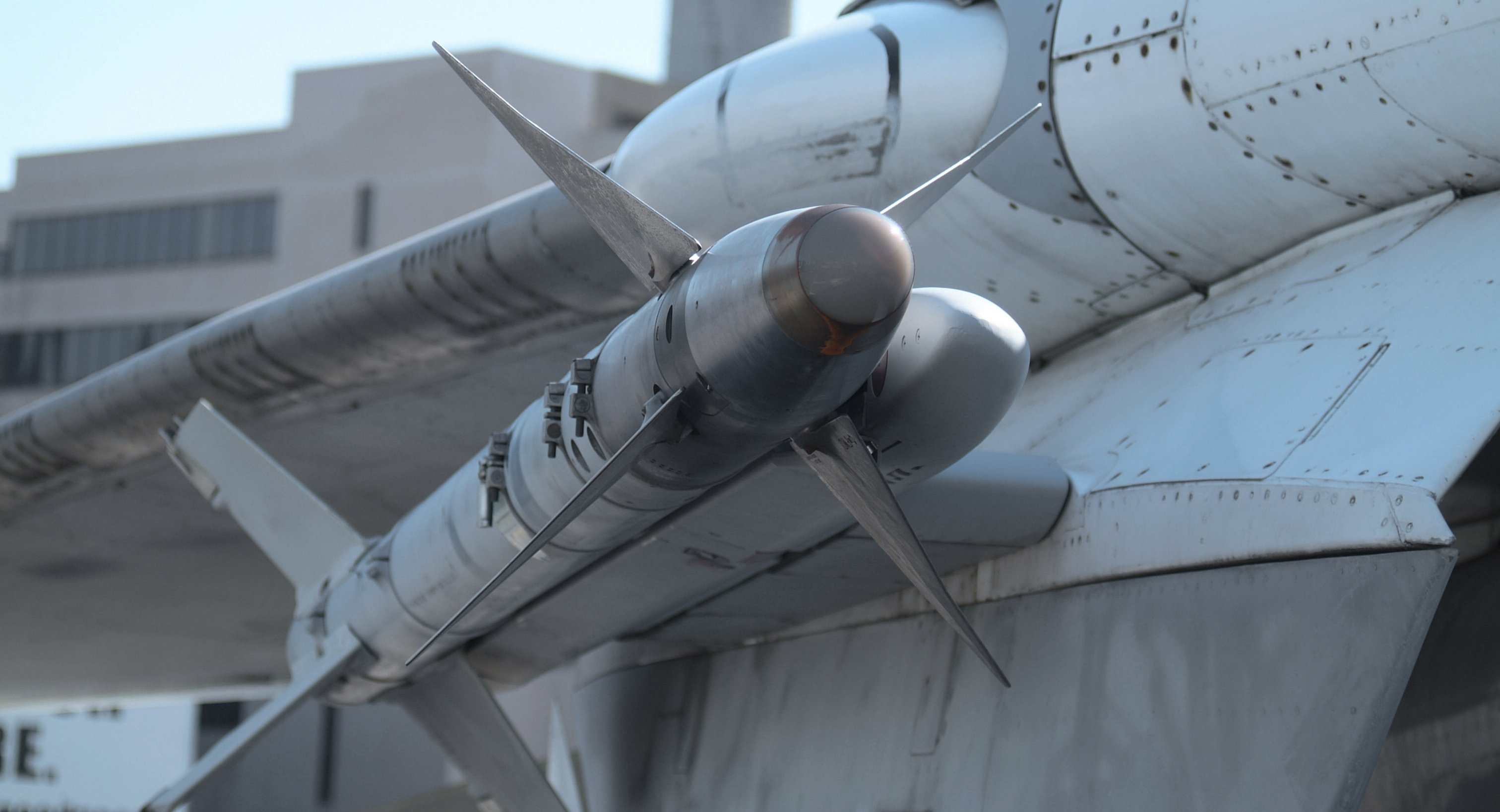

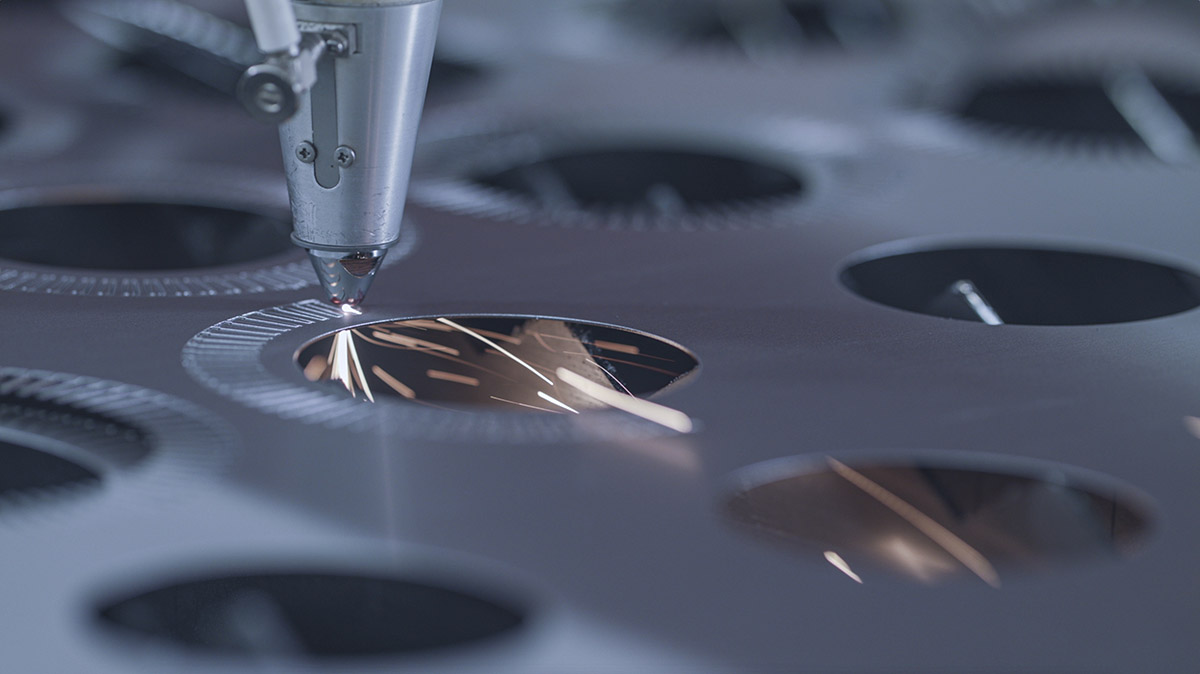

Experience: Production

With lean manufacturing, repeatable processes and quality controls, Kollmorgen can quickly and reliably transition from prototype to full-rate production. Our business system includes Kanban workflow, one-piece flow cells, visual management and sophisticated inventory control. Using the efficient production processes we have developed to supply our broad range of commercial off-the-shelf products and standard modifications, we make sure your motors get out the door the same way, on time, every time.

![]() Key Milestone: Production readiness review

Key Milestone: Production readiness review

Resources: Ongoing Production and Program Support

Time and again, Kollmorgen has proven our ability to sustain the product availability, quality and performance required for long-term, large-scale defense programs. We know how to comply with export, cybersecurity and other requirements. We know how to engage in preferred supplier programs designed to ensure timely, defect-free delivery. And we know how to manage costs for the success of your program throughout its lifecycle.

![]() Key Milestone: Periodic program reviews

Key Milestone: Periodic program reviews

Ready to Discover all Your Defense System is Capable of?

Use our advanced design tools to get a quick start choosing the right motors for your application. Then rely on our co-engineering expertise to achieve the exact specifications and modifications you need for optimum performance, quality, manufacturability and cost. Kollmorgen’s self-service, web-based design tools include:

Product Selectors

For direct selection of products when you already know your torque, speed, sizing and other requirements.

Motioneering

For guided product selection when you know your application requirements but not the necessary torque and speed.

Performance Curves

For visualizing speed and torque based on winding factor, ambient temperature, drive current and other factors

Explore All our Design Tools »

Get Started

Count on Kollmorgen support to help you design and build a successful machine and keep it reliably productive, anywhere in the world. Our co-engineering experts will work with you to tailor a perfect-fit solution for your motion requirements.

For more than 100 years, Kollmorgen has been creating innovative solutions that bring big ideas to reality, keep the world safer and improve lives. Our history of reliability is unsurpassed, and our solutions are supported through engineering centers of excellence and customer service in all major regions of the world.

See the Kollmorgen Global Footprint | Discover the Kollmorgen Difference