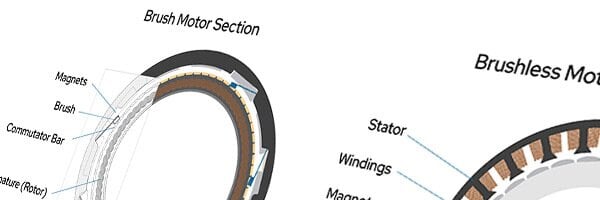

Brushless motors dominate the market, and with good reason. Learn the design principles, benefits and best uses for both motor types in our new blog.

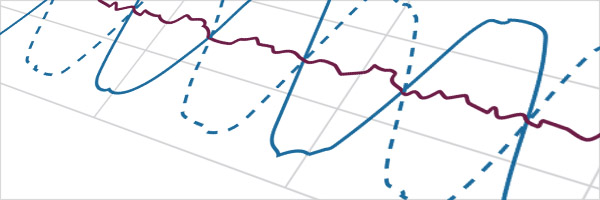

There’s a lot of fog in the market surrounding cogging torque, its effect on torque ripple, and how to achieve the smoothest motion for EO/IR imaging. Let Kollmorgen's experts clear it up.

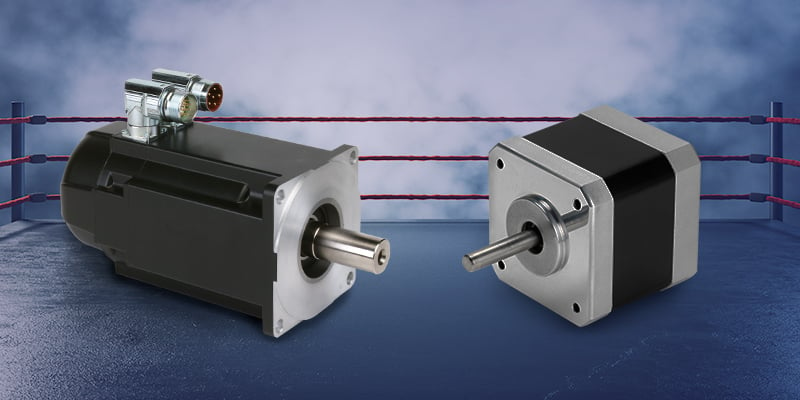

What is the best motor technology to use in a motion control application? There are numerous technologies to create motion, from hydraulic to pneumatic or electromechanical. In the world of precision motion control, many machine designers face a…

The automation industry is growing fast, driven by initiatives such as Industry 4.0 and Made in China 2025, as well as the recent boom in online shopping. To keep up with competition and the increased demand for automated guided vehicles and mobile…

From the surface of Mars to the depths of the ocean, from the core of the earth to the core of the human body, Kollmorgen motion systems take on the most extreme environments.

Knowing how to selct a stepper motor is critical for optimal performance. Use our speedy, dependable Stepper Optimizer tool for precise selection.

A stepper motor is a simple two phase brushless synchronous motor containing a segmented magnetized rotor and a stator consisting of a prescribed number of electromagnetic coils. When energized, these coils create north and south polls that push or…

There are several considerations when selecting a direct drive linear actuator for a specific application, such as the required speed, force, motion profile, available physical envelope, and environmental factors. This means the chosen actuator…

The purpose of an AGV system is efficient transportation of goods in a specified environment. The AGV system is a big investment, so it is desirable to have a high degree of utilization as well as a high ratio of deliveries per hour to get a good…

A direct drive linear actuator, using a permanent magnet linear servo motor produces force and velocity based on the supplied current and voltage and provides a linear movement along the axis being driven. The linear servo motor works as part of a…

Companies working toward the consumer market have long invested in and understood the value of user experience (UX) design. A good user experience is a key differentiator in today's market, and by aligning your company to ensure that your customers…

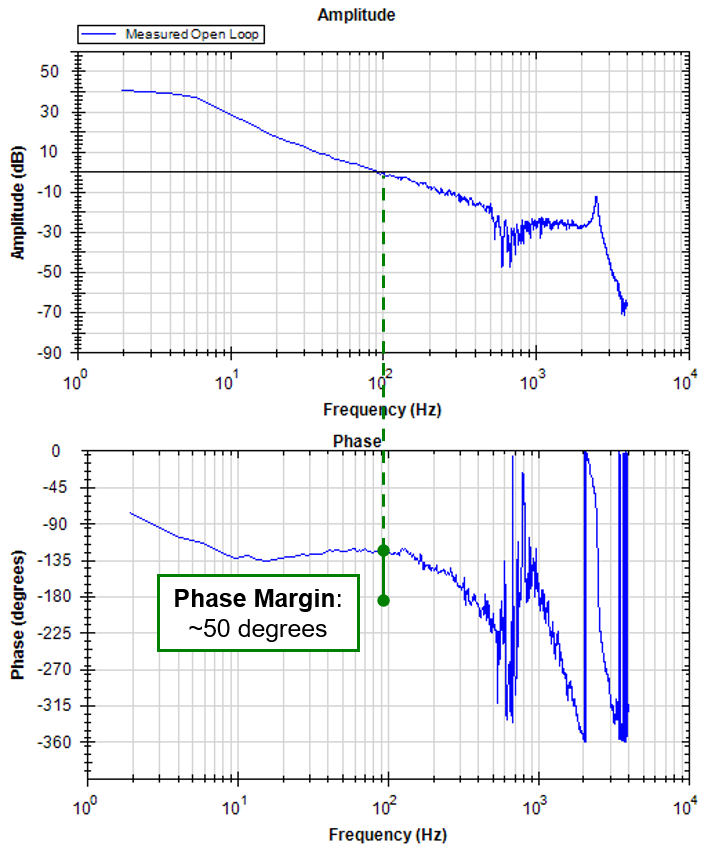

Phase margin is a measurement in the frequency domain, taken from a Bode plot, that calculates the amount of phase lag above -180 degrees at the point on the amplitude plot that crosses 0dB (gain cross over frequency).

Kollmorgen Automation is part of Kollmorgen, which in turn belongs to the NASDAQ-listed Altra Industrial Motion group. The company develops and sells products and services related to automation solutions for applications that include warehousing and…

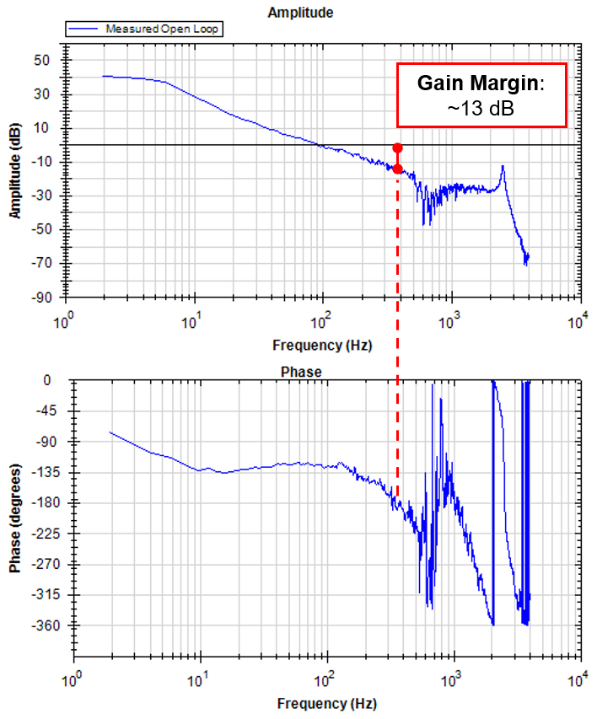

Amplitude gain margin is a measurement in the frequency domain, taken from a Bode plot, that takes the amplitude below 0 dB at the lowest frequency point that the phase reaches -180 degrees (phase crossover frequency).

A servo drive should be selected based on the specific servo motor used in the application. Find out ho to select a servo drive for your application.