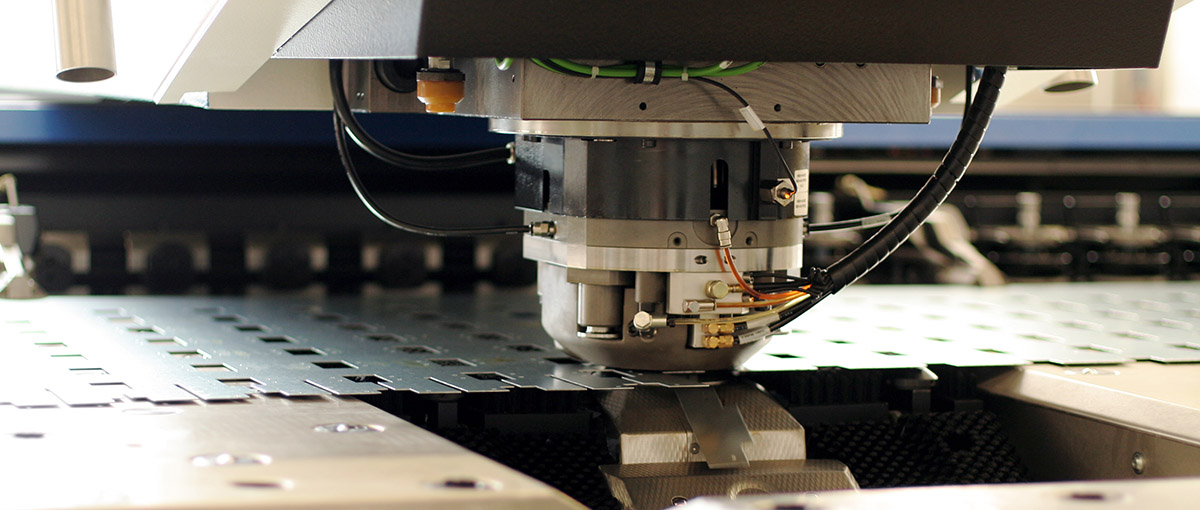

A compact, efficient machine is a better machine. We offer an exceptionally broad range of high-precision motors with standard and custom options to accommodate any requirement in the most compact footprint while maintaining the greatest range of motion.

Our servo systems deliver the ultimate in control, with rotary and linear designs, plus direct drive motors that couple directly to the load for the ultimate precision. And our enhanced stepper designs deliver near-servo positioning without the need for feedback devices. Ready to learn more?