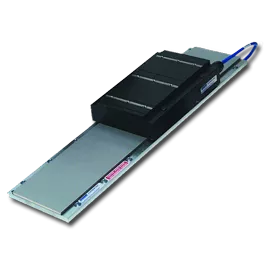

Progress begins with performance. Our high-performance servo motors include direct drive rotary, linear, frameless, explosion proof, washdown and other options to provide superior motion performance for every machine technology, application and operating environment.

Machine tool capabilities depend on more precision at higher speeds with motion tuned to their exacting application requirements. To achieve the greatest possible precision and repeatability for shaping, grinding, drilling or other applications, shaping machines need to eliminate backlash and chatter while ensuring safety and design compliance.

Kollmorgen understands these challenges. For over 100 years, Kollmorgen’s motors, drives and controls have provided machine tool builders with innovative solutions with the optimum motion design, integration and performance for each individual machine. From milling and routing to boring and turning, if a machine tool requires precision motion control, Kollmorgen has a solution.

More Ambitious Machine Design

More Capable Integration, Customization and Performance

Because we understand machine tool equipment, our products integrate seamlessly with industry-standard and custom controllers.

- The Kollmorgen Automation Suite combines the best of a standard control solution with your custom machine requirements.

- Drives with SafeMotion options built-in offer minimal downtime and enhanced operator safety to achieve the ideal system for any machine tool application.

More Confident Engineering and Delivery

Through our co-engineering and co-development capabilities, you can customize our products to help you design lighter, more efficient machines using fewer and smaller parts. Our self-guided design tools help you model, choose and optimize products online, and with direct engineer-to-engineer access, you can address your specialized shaping machine requirements.

Top Products for Machine Tool Applications

Related Resources