PACKAGING: DECENTRALIZED SOLUTION AKD-N DRIVES AND AKM MOTORS FOR DIRECT MAILING

AN EXCELLENT PRESS MAILING SERVICE

Decentralizing the system to reduce space and materials

Promotional postcards and flyers, membership cards, coupons and other info materials fill up our mail boxes daily and encourage shopping tailored to you. Do we ever ask ourselves where all this comes from? The answer is probably from creative minds based in marketing companies. That’s true, when it’s about the idea. However, who produces and makes all of this? A mailing house. Correct! But how? The answer is provided by engineers and planners at C.M.C. srl with the support of Kollmorgen’s decentralized solutions.

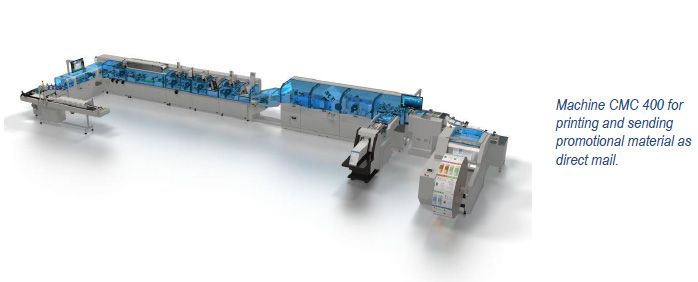

C.M.C. srl is an Italian company based in Città di Castello (Perugia) since 1980. They are leaders in developing solutions and innovative systems in the fields of mailing, graphics and packaging on demand. The company is able to offer high-speed machines for managing envelope inserts which are completely integrated within the production line,reading and printing systems. C.M.C. is a proud pioneer in automated mailing: C.M.C. machines can process up to 30,000 envelopes per hour with detailed digital printing tailored to your needs. Thanks to our strong engineering and informatics department, the company is able to promptly deliver on clients’ needs and can speed up the variable packaging program when sending out the materials and in the finishing process.

One of the last challenges this company took on was that of creating a customized plant which could answer to the needs of a major enterprise at European and international level. It consisted in printing and sending out publicity materials which needed to print promotional coupons in a short frame of time] and at the highest quality as well as being custom made. A head start we had on this project was consolidated technology that is market proven. Its strength, however, was the winning idea: the machine was revolutionized and tailored to the needs of the client, thanks to our own research and development department, strong communication with the client on the one hand and the support of Kollmorgen on the other. The challenge was to produce high quality print on fine coated paper, customize, pack and send the materials with the maximum precision, quality and possible speed.

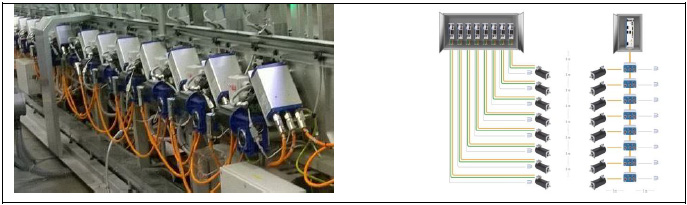

“For years we tried to reduce the switchboard dimensions” said Enrico Martinelli – Production Manager Mailing Department, and Maurizio Giacchi, Sales Manager. Thanks to Kollmorgen’s solutions we were able to decentralize each drive along the three production lines that are part of the plant”.

Every line is made up of three machines equipped with 24 stations matching the number of coupons, some which were customized, whilst others were standardized. The objective was achieved by removing the control panel drives used previously and therefore drastically reducing the size of the switchboard, number and length of cables involved: from a four-frame stand-alone one built on alongside the machine and two meters wide, we moved to an integrated electric switchboard, saving in the process some external space. The AKD-N series drives, installed close to the motor only have one connection cable. The client also benefits from this since they are able to save space for the materials: this transformed the machine to improve efficiency at reduced cost (Total Cost of Ownership).

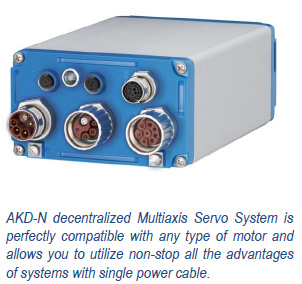

AKD-N Multiaxis Servo Amplifier System: the winning input

The keystone to this project was the use of the AKD-N Multiaxis Servo Amplifier System, an innovative technology with excellent performance that comes in extremely compact size. Thanks to the robust structure and the IP67 protection class, the new decentralized AKD-N Kollmorgen servo drives can be placed close to the motor. Plugin connections, freedom of choice of motor , most suitable mounting point , and wide range of functions: these decentralized AKD-N servo drives can offer complex Motion Control systems with EtherCAT fieldbus and/or other automated interfaces such as ProfiNet, EtherNet I/P and Modbus TCP/IP. The system offers everything that’s necessary for new generation machines without losing out on the simplicity. Power supply as well as safety (STO) and EtherCAT fieldbus are combined in one single hybrid cable of only 11mm diameter. On the motor side there is also only one cable needed for power, brake control and feedback. This leads to more than 80% of machine cable savings.

AKD-N Servo Amplifier - Benefits

- More compact machines

- Smaller and lighter integrated switchboards

- Servo amplifier placed closer to the machines

- Robust structure made of protection class IP67, no need for protective casing

- Easy to clean and service for hygienic environments

- High operating security - thanks to the robust structure

- Faster machine debug and test thanks to less cabling

- Higher flexibility in machine design (modularity and scalability)

C.M.C. has attained the highest benchmark through Kollmorgen components and in choosing a decentralized solution. Kollmorgen is a specialist in Motion Control solutions offering a wide range of servo drives, servo amplifiers, prewired cabling and technical support with the highest level of experience, providing step-by-step support to the client during the entire project development. The global scale of the Kollmorgen brand has enabled C.M.C. to venture in the US and to tap into established markets.

AKM, a step further

In terms of motors, even the wide range of AKM™ Servo Motors contributed to C.M.C. choosing Kollmorgen as their partner in this project: AKM™ practically has an unlimited number of configurations and therefore allows for unprecedented choice and flexibility as well as top-level performance and an excellent power density. It is worth noting that the AKD™ servo drives are easy to set up and use thanks to their plug-and-play motor recognition and self-adjustment.

Conclusion

“I’m really pleased to be working with the C.M.C. team, it’s a dynamic company, full of innovative ideas, with young and talented staffs – concludes Fabio Massari, Senior Sales & Key Account Manager at Kollmorgen. Working closely from the start with the management team and being able to share our respective needs has allowed us to provide a solution, which in this specific case has brought about a reduction in the amount of cabling used; from the old system which required 1,500 meters down to 240 meters. We were able to save on more than one entire kilometer of cabling. I hope that we will be able to undertake new challenges ahead together, with the added value that has allowed us to stand out to date”.

Author: Senior Sales & Key Account Manager, Kollmorgen Italy, KOLLMORGEN Italia

Author: Senior Sales & Key Account Manager, Kollmorgen Italy, KOLLMORGEN Italia

ABOUT KOLLMORGEN

Since its founding in 1916, Kollmorgen’s innovative solutions have brought big ideas to life, kept the world safer, and improved peoples’ lives. Today, its world-class knowledge of motion systems and components, industry-leading quality, and deep expertise in linking and integrating standard and custom products continually delivers breakthrough solutions that are unmatched in performance, reliability, and ease-of-use. This gives machine builders around the world an irrefutable marketplace advantage and provides their customers with ultimate peace-of-mind. For further information please contact [email protected] or visit our website www.kollmorgen.com/uk