In our last blog related to decentralized drives, we indicated several key customer benefits tied to using this approach. First, you can reduce your cable costs significantly in machine configurations with lots of axes spread apart throughout the machine. Second, a reduction in cabinet space and cooling requirements since you’ve taken a number of heat producing elements (Servo drives) from the enclosure. Thirdly, you increase flexibility in design. In this blog entry, we will explore what is meant by flexibility and how this offers several advantages.

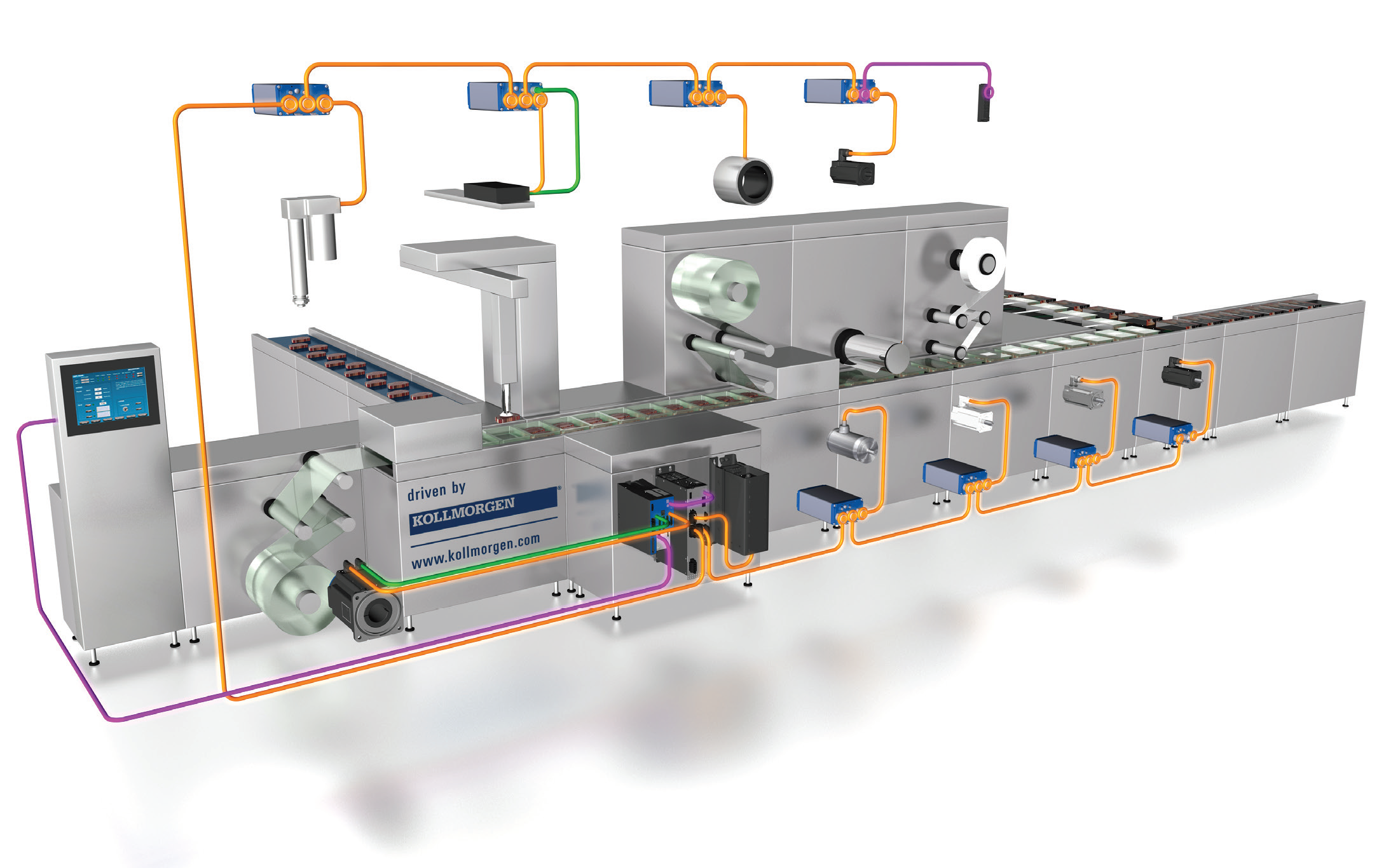

In many processing and factory automation machines, it is possible that there is a combination of methods that feed material into, and exiting from the machine, some requiring quick precise control. In other situations, specific product may require additional steps based on its particular design. Using a decentralized drive approach, the machine builder can design machinery that allows for these “optional” configurations easily. In essence, you create the ability to offer “plug and play” attachments which provides tremendous flexibility for the end users of the machinery.

What about adding options in the field? No problem – again, the plug and play nature of the decentralized solution offers the machinery builder to consider new ways to sell the machine, along with field installable upgrades. Customers can purchase a lower cost machine initially, and later add on options that increase the machines capabilities (like an additional feeder, or discharge mechanism), as production demands increase.

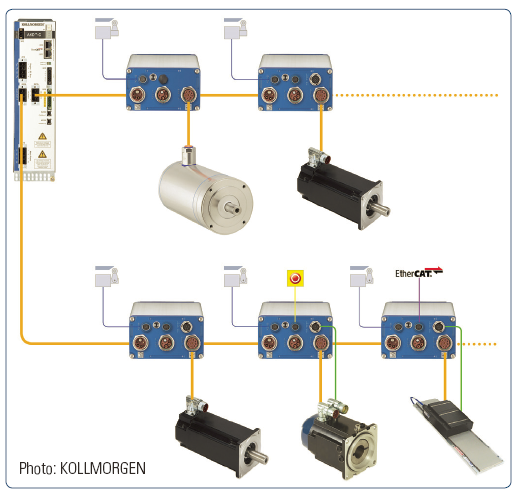

There are a variety of solutions we would consider that make up a decentralized system, including integral motor/drive combinations, as well as “near” drives mounted in the vicinity of the motor it is driving. A key advantage of the “near” drive approach, like the Kollmorgen AKD-N, is in it’s flexibility to be paired with a variety of motor solutions. So again, we hit on flexibility with regards to this kind of decentralized approach as the machine builder can better optimize the servo requirements by choosing the best servo motor solution, regardless of technology. This can be a huge advantage over integral designs as the machine builder can utilize conventional servos, direct drive rotary or linear, frameless, or other servo controlled actuator assemblies.

A key feature related to the Kollmorgen AKD-N product offering is the utilization of a single cable approach and EtherCat fieldbus network. This facilitates the ability to daisy chain the necessary power, feedback, and fieldbus communications from drive to drive. Adding another drive to the link is as easy as connecting the new drive into the network. Additionally, the AKD-N solution can also play well with conventional “centralized” solutions as well where a very high power axis may require a higher current drive.

Decentralized solutions – lower cable costs, reduced cabinet sizes, less cooling, flexibility – all add up to a great solution for precision motion along with cost savings!